- Home

- About Us

-

product

- Colour

- Black

- White

-

additive

- Anti-Slip Masterbatch

- Conductive Compounds

- Optical Brighteners

- Desiccants (Moisture Absorption)

- Flame Retardants Masterbatch

- Anti-microbial Masterbatch

- Nucleating/clarifier Additives

- Anti-statics Masterbatch

- Anti-block Masterbatch

- Polymer Processing Aids (PPA)

- Antioxidant Masterbatch

- Bio Digradeble Masterbatch

- Customised Additive

- special master batch

- application

- Quality

- Downloads

- Career

- Why Us?

- Contact

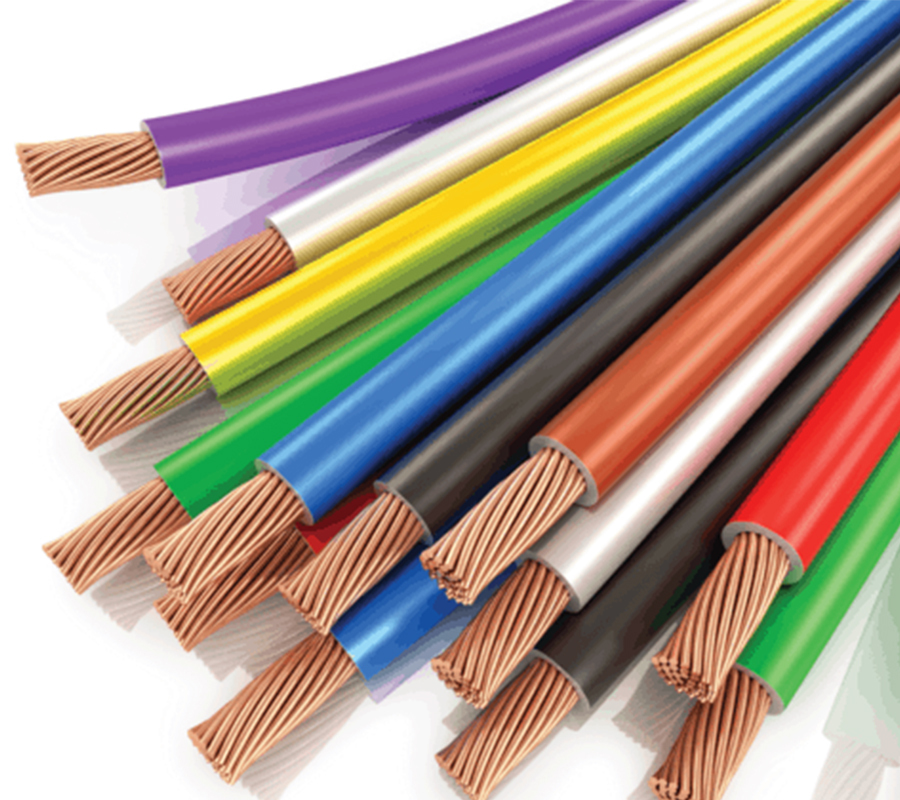

Cable coating extrusions are a specialized process used in the manufacturing of electrical cables. This method involves applying a protective coating of plastic material onto metal wire cores, enhancing their durability, insulation properties, and resistance to environmental factors.

The cable coating extrusion process begins with feeding the metal wire cores through a heated extruder barrel, where the plastic material is melted to a viscous state. The molten plastic is then forced through a die that shapes it around the wire cores, forming a uniform coating. This coating serves to insulate the wires, protecting them from moisture, abrasion, and electrical interference.

Various types of plastics can be used for cable coating extrusions, including PVC, polyethylene, and polypropylene, chosen based on the specific requirements of the application. Additionally, additives such as flame retardants and UV stabilizers may be incorporated into the plastic formulation to enhance the performance and longevity of the cable coatings.

Cable coating extrusions are crucial in the production of a wide range of electrical cables, including power cables, communication cables, and fiber optic cables. By providing reliable insulation and protection, these extrusions ensure the safe and efficient transmission of electricity and data in diverse industries and applications.